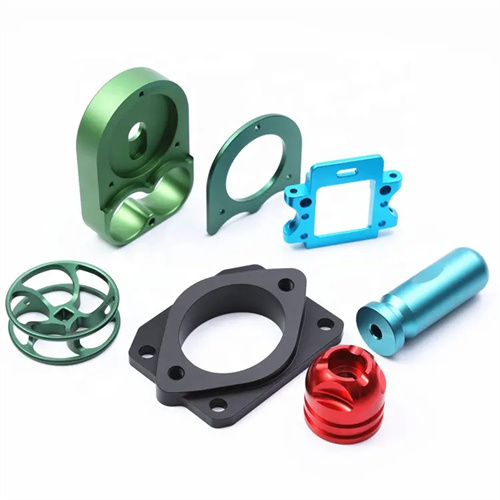

Streamlined Processes for Rapid Custom CNC Turning Parts Production

Our streamlined production processes form the foundation of fast delivery for Custom CNC Turning Parts, ensuring urgent projects meet tight deadlines. We’ve reengineered our workflow to eliminate bottlenecks, implementing a lean manufacturing approach that reduces setup times by 40% compared to traditional methods. Our quick-turn cells operate 24/7, dedicated exclusively to urgent Custom CNC Turning Parts orders with prioritized scheduling. We use standardized work instructions and pre-programmed CNC templates for common part geometries, allowing us to begin machining within hours of order confirmation. Material handling is optimized with kitting systems that prepare raw stock for immediate use, minimizing wait times between production stages. This process efficiency enables us to deliver simple Custom CNC Turning Parts in as little as 24 hours and complex components within 3–5 days, providing reliable speed without sacrificing precision.

Resource Allocation for Urgent Custom CNC Turning Parts

Strategic resource allocation ensures we meet the demands of urgent Custom CNC Turning Parts projects without compromising quality. We maintain a dedicated team of skilled machinists trained specifically in fast-turn production, available for overtime and weekend shifts to accelerate delivery. Our facility operates with spare CNC turning capacity—including multi-axis machines with live tooling—that can be immediately allocated to urgent Custom CNC Turning Parts orders. We stock a large inventory of common materials (aluminum, brass, steel, titanium) in various sizes, eliminating material lead times that often delay production. Tooling is pre-loaded in dedicated carts for quick changeovers, reducing setup time per job to less than 30 minutes. This proactive resource management allows us to scale production rapidly for urgent projects, ensuring Custom CNC Turning Parts are manufactured and delivered on compressed timelines.

Technology-Driven Speed for Custom CNC Turning Parts

Advanced technology enables us to achieve exceptional speed in Custom CNC Turning Parts production while maintaining precision for urgent projects. Our high-speed CNC turning centers operate at spindle speeds up to 60,000 RPM, reducing cycle times by 30% compared to conventional machines. We use AI-powered CAM software that generates optimized tool paths in minutes, accelerating programming for complex Custom CNC Turning Parts. Automated loading/unloading systems minimize machine idle time, ensuring continuous production even during operator breaks. In-process measurement technologies eliminate post-machining inspection delays by verifying dimensions during production. This technological integration allows us to produce Custom CNC Turning Parts at faster rates without sacrificing accuracy, meeting the dual demands of speed and precision required for urgent applications.

Communication and Coordination for Custom CNC Turning Parts Delivery

Transparent communication and tight coordination are critical to delivering urgent Custom CNC Turning Parts on time. We assign dedicated project managers to every urgent order, serving as single points of contact for clients throughout the production process. These managers provide real-time updates via a secure online portal, allowing clients to monitor their Custom CNC Turning Parts’ progress from design to delivery. We hold daily production meetings focused on urgent projects, addressing potential delays before they impact timelines. Our engineering team collaborates with clients upfront to identify design optimizations that accelerate machining without affecting performance, such as simplified geometries or standard tolerances where possible. This proactive communication ensures alignment between client expectations and production capabilities, minimizing revisions that could delay Custom CNC Turning Parts delivery.

Quality Assurance in Fast-Track Custom CNC Turning Parts Production

Maintaining rigorous quality standards during fast-track production ensures urgent Custom CNC Turning Parts meet specifications without compromise. We’ve integrated automated inspection systems that perform 100% dimensional checks at production speeds, eliminating the trade-off between speed and quality. Our statistical process control (SPC) software monitors critical parameters in real time, flagging any deviations that could affect Custom CNC Turning Parts quality. We use dedicated tooling for urgent projects to prevent cross-contamination and ensure consistent performance. Final inspection for urgent Custom CNC Turning Parts is prioritized, with specialized inspectors assigned to verify compliance with client specifications. This commitment to quality ensures fast-delivered Custom CNC Turning Parts meet the same standards as our regular production, providing reliable performance for critical applications.

Client Success Stories with Fast Delivery Custom CNC Turning Parts

Our track record of delivering urgent Custom CNC Turning Parts has made us a trusted partner for clients facing critical deadlines. We supported an aerospace client with a production line emergency, delivering replacement valve components within 48 hours to prevent a costly shutdown. A medical device manufacturer relied on us to produce prototype Custom CNC Turning Parts in 72 hours, enabling them to meet regulatory testing deadlines. For an automotive supplier facing a supply chain disruption, we ramped up production to deliver 10,000 Custom CNC Turning Parts within a week, maintaining their assembly schedule. These success stories demonstrate our ability to balance speed, quality, and communication for urgent projects. Clients trust us to deliver Custom CNC Turning Parts on time, even under the most demanding circumstances, making us their go-to partner for critical, time-sensitive applications.