OUR CAPABILITIES

Aluminum Alloy CNC Turning

Our Aluminum Alloy CNC Turning deeply explores the characteristics of light weight, corrosion resistance, and good heat dissipation of aluminum alloys. With the help of advanced CNC lathe equipment, we efficiently process rotating aluminum alloy parts. Whether it is precise turning of slender shafts or forming of complex surfaces, we can ensure strict dimensional tolerances and excellent surface smoothness of parts through high-precision tool path planning and stable machining parameter control.

Brass Copper CNC Turning

Our Brass Copper CNC Turning fully utilizes the excellent cutting performance and thermal conductivity of brass and purple copper. By optimizing the CNC turning process, from precision copper threaded parts to complex shaped copper parts, we rely on high-precision lathes and professional technical teams to accurately control the outer diameter, inner diameter, taper and other parameters of the parts, creating high-precision and beautifully designed copper rotary products that meet the needs of industries such as electronics and instrumentation.

Custom CNC Turning Parts

Our Custom CNC Turning Parts always prioritize meeting customers' personalized needs. Starting from receiving unique design concepts and processing requirements from customers, combined with rich turning experience and advanced technology, we carefully design exclusive turning solutions based on different material characteristics and structural features. From raw material selection to finished product polishing, every link is strictly controlled to customize high-quality CNC turning parts for customers.

Precision CNC Turning Service

Our Precision CNC Turning Service is equipped with an experienced technical team and advanced testing equipment to strictly inspect and control key indicators such as roundness, cylindricity, and surface roughness of parts. Whether it is precision shafts for semiconductor equipment or core rotating components for medical devices, they can be delivered with ultra-high precision, providing reliable guarantees for the high-end manufacturing field.

Stainless Steel CNC Turning

Our Stainless Steel CNC Turning faces the machining challenges brought by the high strength and hardness of stainless steel. By selecting special coated tools and optimizing cutting parameters, we achieve efficient and high-precision turning of stainless steel rotary parts. From shaft parts of food processing equipment to corrosion-resistant pipe fittings of chemical machinery, we rely on mature processing technology and rich experience to ensure the strength and corrosion resistance of parts while ensuring their dimensional accuracy and surface quality.

Metal CNC Turning

Our Metal CNC Turning is capable of efficiently and accurately turning various metal materials, such as carbon steel, stainless steel, aluminum alloy, copper alloy, etc., through advanced CNC lathe equipment. We precisely control parameters such as lathe speed, feed rate, and cutting depth to ensure that the processed metal parts have extremely high dimensional accuracy and surface quality. We can achieve a perfect transformation from blank to finished product for both simple cylindrical parts and complex irregular rotating parts.

CNC Turning Parts Manufacturer

Multi Materials for CNC Turning Parts

Our Services

Not only that, we also provide ODM&OEM services to meet the diverse needs of different customers. Service is not a one-time purchase. After delivery, we continue to provide support and respond to your needs at any time. With professionalism and sincerity, we have become your trusted long-term partner in the field of precision CNC turning.

OUR SERVICES

Quick Prototyping Service

We understand the customer's need for quick sample acquisition during the early stages of product development, so we have specifically established a fast sampling service. By utilizing advanced CAM programming technology and efficient processing equipment, we can produce high-quality samples for you in the shortest possible time. Usually, we can complete the conversion from drawings to samples within a few working days, helping you quickly advance the product development process and reduce development cycles and costs.

Plating Services

We not only provide high-quality CNC turning machining, but also offer professional surface treatment services to enhance the overall performance of parts. According to your needs, we can perform electroplating (galvanizing, nickel plating, etc.), spraying, anodizing, and other treatments on the processed parts to effectively enhance their wear resistance, corrosion resistance, or give them a unique appearance effect, allowing the parts to exhibit excellent performance and beautiful appearance in various usage scenarios.

Customized Solution Services

We are well aware that each customer's needs are unique, so we are committed to providing customized solutions for our customers. Whether it's special part dimensions, precision requirements, or unique functional requirements and production processes, we will have in-depth communication with you to understand your specific needs and goals. Then, combining our own technological advantages and rich experience, we will tailor a customized processing plan for you, from tool selection, programming strategy to processing sequence, to ensure that the final product fully meets your expectations.

Manufacture

Bevel Gear Processing Technology

Turning Of Cast Iron Bearing Seats

Cast Iron Names, Codes And Grades

Turning Of Large Diameter Outer Spherical Surface Of Cast Iron

Turning Of Shaft Workpieces

Calculation Of Geometric Dimensions Of Straight Bevel Gears

Processing Technology Of Long Lead Screw

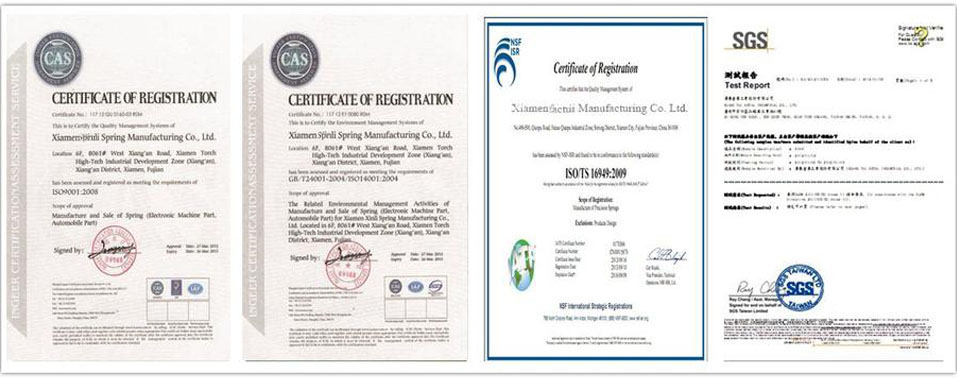

OUR CERTIFICATES