Steel product brand designation

Steel product grades are important identifiers for identifying the composition, properties, and uses of steel materials. my country’s current steel product grade designation system, based on GB/T 221-2008, “Method for Designation of Steel Product Grades,” uses a combination of Chinese phonetic letters, chemical element symbols, and Arabic numerals to intuitively reflect the type, chemical composition, and mechanical properties of steel materials. A well-defined and standardized designation system not only facilitates production, use, and management but also provides a crucial basis for material selection and process design. The components of a steel product grade include a prefix symbol, chemical element symbol, content number, and suffix symbol. Different types of steel materials (such as carbon steel, alloy steel, and stainless steel) have specific designation rules that require accurate understanding and application.

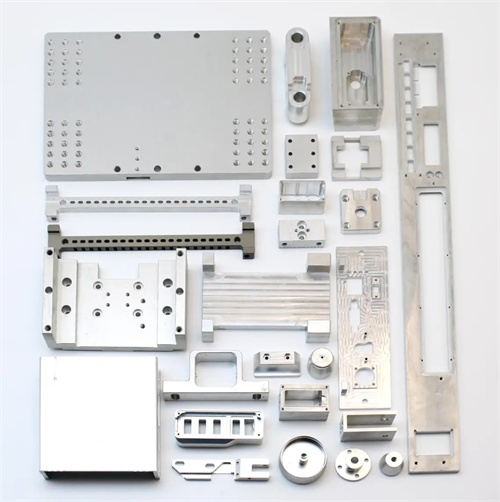

The designation system for carbon steel grades is centered around average carbon content, combined with the steel’s intended use and quality grade. The designation for carbon structural steel consists of the initials “Q” (the pinyin for “Qi” in Chinese), representing yield strength, the yield strength value, the quality grade symbol (A, B, C, D, in ascending order), and the deoxidation method symbol (F for rimmed steel, b for semi-killed steel, Z for killed steel, and TZ for special killed steel; Z and TZ are optional). For example, Q235B designates Grade B killed carbon structural steel with a yield strength of 235 MPa, suitable for general structural components such as buildings and bridges. The grade of high-quality carbon structural steel directly uses two digits to indicate the average carbon content (in parts per ten thousand). For example, 45 steel indicates high-quality carbon structural steel with an average carbon content of 0.45%, which is often used to manufacture gears, shafts and other parts that require tempering treatment. If it is rimmed steel, “F” is added after the number. For example, 08F indicates rimmed steel with an average carbon content of 0.08%, which has good plasticity and is suitable for stamping.

Alloy steel designations, based on carbon steel, incorporate the type and content of alloying elements, clearly reflecting their influence. Alloy structural steel designations consist of two digits (indicating the average carbon content in parts per thousand), the symbol of the alloying element, and the percentage of the average content (no digit is indicated for average content <1.5%, "2" for 1.5%-2.49%, "3" for 2.5%-3.49%, and so on). For example, 40Cr designates an alloy structural steel with an average carbon content of 0.40% and a chromium content of 0.8%-1.1%. After quenching and tempering, it exhibits excellent overall mechanical properties and is commonly used in machine tool spindles. 20CrMnTi designates an alloy structural steel with a carbon content of 0.20% and chromium, manganese, and titanium contents of <1.5%. It is suitable for carburizing and quenching and is used in the manufacture of wear-resistant parts such as gears. The method of expressing the carbon content of alloy tool steel is different from that of alloy structural steel. When the carbon content is ≥1.0%, the carbon content is not marked. When it is <1.0%, it is expressed in thousandths. For example, 9SiCr represents alloy tool steel with a carbon content of 0.9% and silicon and chromium contents of <1.5%. It is suitable for manufacturing cutting tools such as taps and dies.

The designation system for stainless steel and heat-resistant steel focuses on alloying element content, as their performance is primarily determined by the content of alloying elements such as chromium and nickel. Stainless steel designations were either indicated by the initials “B” (in Chinese pinyin) for “stainless” (不穀) (old standards) or directly by the alloying element symbols and content (new standards). However, the current standards prefer to use internationally recognized chemical element symbols and content designations. For example, 06Cr19Ni10 designates austenitic stainless steel with an average carbon content of 0.06%, 19% chromium, and 10% nickel. It offers excellent corrosion resistance and weldability and is widely used in food processing equipment. Heat-resistant steel designations are similar to stainless steel. For example, 12Cr1MoV designates heat-resistant steel with a carbon content of 0.12%, chromium of 1%, and molybdenum and vanadium content of less than 1.5%. It can be used for long-term operation below 540°C and is suitable for high-temperature components such as boilers and steam turbines. Furthermore, precipitation-hardening stainless steels are suffixed with “PH,” such as 07Cr17Ni7AlPH, indicating that their high strength is achieved through precipitation hardening.

Special-purpose steel grades are designated with targeted designations to highlight their unique properties and applications. Cast steel grades are designated by the initials “ZG” (Chinese pinyin for “cast steel”) followed by the minimum tensile strength value. For example, ZG270-500 indicates a cast steel with a tensile strength of 270 MPa and an elongation of 500%, used to manufacture complex parts such as valve bodies and cylinder blocks. Bearing steel grades are designated by the initials “G” (Chinese pinyin for “roll”) followed by the carbon content (in parts per thousand) and chromium content. For example, GCr15 indicates a high-carbon chromium bearing steel containing approximately 1.0% carbon and 1.5% chromium. This steel possesses high hardness and wear resistance, and is the core material for rolling bearings. Furthermore, free-cutting steels are designated by adding the initials “Y” (Yi) to their designations, such as Y12, which improves cutting performance by adding elements like sulfur and lead. Low-alloy, high-strength steels are designated by adding the alloying element symbol after “Q,” such as Q345GNHD, which indicates a weather-resistant, high-strength steel with a yield strength of 345 MPa, suitable for outdoor structures like bridges and containers. Understanding the meaning of these special designations is crucial for selecting and using steel materials appropriately.