In the dynamic and competitive world of sports goods, we firmly believe that Stainless Steel CNC Turning is a transformative manufacturing approach that significantly enhances the performance, durability, and safety of our athletic equipment. Stainless steel, with its remarkable corrosion resistance, high strength, and excellent wear – resistance, when combined with the precision of CNC turning, empowers us to create components that meet the diverse and exacting demands of athletes at all levels. From the robust frames of bicycles to the intricate parts of fitness equipment, Stainless Steel CNC Turning plays a pivotal role in every aspect of sports goods production. Let’s explore how this technology revolutionizes our approach to crafting sports products.

1. High – strength Frames and Structures: Stainless Steel CNC Turning for Bicycles and More

We understand that the structural integrity of sports equipment is crucial for both performance and safety, and Stainless Steel CNC Turning is essential for manufacturing high – quality frames and structures. In the cycling industry, stainless – steel frames offer a perfect balance of strength and lightweight design. Custom – turned stainless – steel tubes produced through CNC turning can be precisely shaped to fit the specific requirements of different bicycle models, whether it’s a road bike, mountain bike, or a track bike.

For example, in a recent project for a professional cycling team, we used Stainless Steel CNC Turning to create custom frames for their time – trial bikes. The precision of the process allowed us to achieve a wall thickness tolerance of ±0.1mm, ensuring that the frames were not only strong enough to withstand the rigors of high – speed racing but also light enough to enhance the cyclists’ performance. The corrosion – resistant property of stainless steel also protected the frames from the elements, such as rain and sweat, extending their lifespan and maintaining their performance over time. Similarly, in the production of sports wheelchairs, stainless – steel frames fabricated through this technology provide durability and stability, enabling athletes to move with confidence.

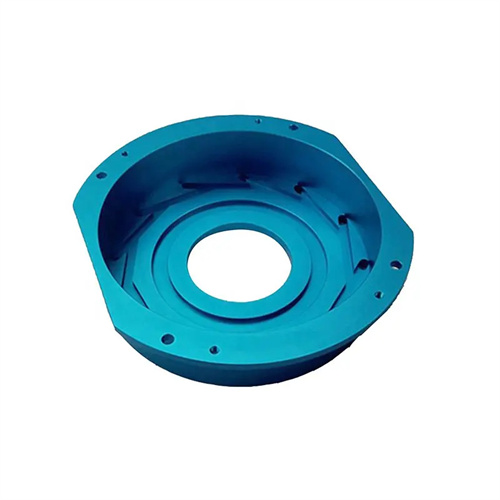

2. Precision – made Components for Fitness Equipment: Stainless Steel CNC Turning

Fitness equipment requires components that can withstand heavy loads and repetitive use, and Stainless Steel CNC Turning offers an ideal solution for manufacturing such parts. In weightlifting machines, for instance, the shafts, bars, and connectors need to be extremely strong and precise. Custom – turned stainless – steel weightlifting bars produced through CNC turning have a high tensile strength, ensuring they can support heavy weights without bending or breaking.

The precision of CNC turning also allows for the creation of smooth surfaces and exact dimensions, providing a comfortable grip for athletes. In a commercial gym equipment manufacturing project, we used Stainless Steel CNC Turning to produce custom – turned pulleys and bearings for cable – based fitness machines. The tight tolerances achieved through this process reduced friction, resulting in smoother operation and increased longevity of the equipment. Moreover, the non – porous surface of stainless steel made these components easy to clean and maintain, meeting the hygiene standards of fitness facilities.

3. Durable and Hygienic Parts for Water Sports Equipment: Stainless Steel CNC Turning

In water sports, where equipment is constantly exposed to water and salt, corrosion resistance is of utmost importance, and Stainless Steel CNC Turning is the go – to technology for manufacturing durable and hygienic parts. For boats and jet skis, stainless – steel propellers and shafts produced through CNC turning can withstand the corrosive effects of saltwater and maintain their performance over time.

The precision of the turning process ensures that these components have the correct pitch and balance, optimizing the speed and efficiency of the watercraft. In the production of swimming pool equipment, such as ladders and handrails, stainless – steel parts fabricated by this method not only provide a secure grip for swimmers but also resist rust and corrosion, ensuring the safety and longevity of the equipment. Additionally, in diving gear, stainless – steel buckles and connectors offer strength and reliability, even in the challenging underwater environment.

4. Cost – effective Production: Stainless Steel CNC Turning for Sports Goods Manufacturing

We are constantly striving to balance quality and cost in sports goods manufacturing, and Stainless Steel CNC Turning offers a cost – effective solution. The automated nature of CNC turning reduces labor costs significantly compared to traditional machining methods. Once the machining program is set up, we can produce multiple stainless – steel components with consistent quality in a relatively short time.

For example, when manufacturing a batch of 2000 custom – turned stainless – steel bike spokes, Stainless Steel CNC Turning reduced the production time per spoke by 30% compared to manual machining, resulting in overall cost savings of 25%. Moreover, the precision of CNC turning minimizes material waste, as parts are machined to exact specifications. The ability to quickly prototype and test new designs using computer – aided design (CAD) integration also saves us from costly rework during mass production, making it an economically viable choice for our sports goods manufacturing operations.

5. Innovation – driven Applications: Stainless Steel CNC Turning for Advanced Sports Gear

As the sports industry continues to embrace innovation, Stainless Steel CNC Turning is at the forefront of driving the development of advanced sports gear. In the creation of smart sports equipment with integrated sensors and monitoring systems, custom – turned stainless – steel enclosures provide a secure and durable housing for the electronic components. The precision of CNC turning allows for the seamless integration of these high – tech features, ensuring accurate data collection and transmission.

In addition, as we focus on sustainable manufacturing, stainless steel’s recyclability makes it an ideal material for eco – friendly sports products. By using Stainless Steel CNC Turning, we can create components from recycled stainless steel without sacrificing precision or quality, reducing our environmental impact. The combination of innovation and sustainability in Stainless Steel CNC Turning enables us to develop cutting – edge sports gear that meets the evolving needs of athletes while contributing to a greener future.