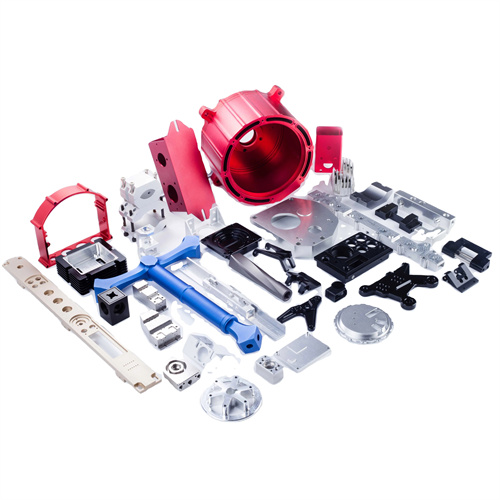

In the fast – paced and highly competitive packaging industry, where efficiency, durability, and cost – effectiveness are key factors, aluminum alloy CNC turning has emerged as a valuable manufacturing technique in our production processes. By taking advantage of the unique properties of aluminum alloys, such as lightweight, corrosion resistance, and strength, along with the precision of CNC turning, we can produce components that significantly enhance the performance and functionality of packaging equipment and products. These parts play a crucial role in various aspects of the packaging industry, from improving the efficiency of packaging machinery to creating innovative packaging solutions, enabling us to meet the diverse needs of our customers and stay ahead in the market.

1. Aluminum Alloy CNC Turning: Fabrication of Packaging Machinery Structural Components

One of the primary applications of aluminum alloy CNC turning in the packaging industry is the fabrication of structural components for packaging machinery. We rely on this technology to create parts that can withstand the rigors of continuous operation while maintaining lightweight and high – strength characteristics.

Using CNC turning machines, we shape aluminum alloy materials into various structural components such as frames, support beams, and mounting brackets for packaging machinery. The high – precision machining process ensures that these components have exacting dimensions and tight tolerances, allowing for seamless assembly and stable operation of the machinery. For example, in large – scale automated packaging lines, aluminum alloy CNC – turned frames provide a sturdy yet lightweight foundation for the entire system. Their corrosion – resistant property also makes them suitable for use in environments with high humidity or exposure to chemicals, extending the lifespan of the machinery. Additionally, the smooth surfaces achieved through CNC turning reduce friction between moving parts, contributing to the overall efficiency and reliability of the packaging machinery.

2. Aluminum Alloy CNC Turning: Production of Packaging Mold and Die Inserts

Molds and dies are essential for mass – producing packaging products, and aluminum alloy CNC turning is used to create high – precision inserts for these tools.

We utilize aluminum alloy CNC turning to manufacture inserts for plastic injection molds, blow molds, and other types of packaging molds. The excellent thermal conductivity of aluminum alloys helps in efficient heat transfer during the molding process, reducing cycle times and improving production efficiency. The high – accuracy machining of CNC turning allows for the creation of inserts with complex geometries and precise dimensions. For instance, in the production of plastic packaging containers, aluminum alloy CNC – turned inserts can be designed with intricate patterns and textures on their surfaces, which are then transferred onto the final packaging products, adding aesthetic value. The precise dimensions of these inserts ensure consistent quality of the molded parts, minimizing the occurrence of defects and reducing waste in the production process.

3. Aluminum Alloy CNC Turning: Creation of Packaging Equipment Fasteners and Connectors

Packaging equipment requires a variety of fasteners and connectors to hold its components together securely, and aluminum alloy CNC turning is employed to produce these essential parts.

We use CNC turning to shape aluminum alloys into bolts, nuts, screws, and other fasteners with precise thread forms and dimensions. The lightweight nature of aluminum alloy fasteners reduces the overall weight of the packaging equipment, making it easier to handle and transport. At the same time, their sufficient strength and corrosion resistance ensure a reliable connection that can withstand the vibrations and stresses during operation. In addition, aluminum alloy CNC – turned connectors such as couplings and adapters are used to join different parts of the packaging equipment. The high – precision machining of these connectors guarantees a secure and tight fit, preventing any leakage or disconnection, which is crucial for the proper functioning of the equipment, especially in applications involving fluids or gases.

4. Aluminum Alloy CNC Turning: Assembly of Packaging Product Handles and Grips

Many packaging products, especially those for consumer goods, feature handles or grips for easy carrying, and aluminum alloy CNC turning is used to create these functional and ergonomic elements.

For cardboard boxes with metal handles, aluminum alloy CNC – turned handles offer a combination of strength and lightweight design. The smooth surfaces and precise shaping of these handles provide a comfortable grip for consumers. In the case of heavy – duty packaging containers, such as toolboxes or storage cases, aluminum alloy CNC – turned grips can be designed with anti – slip textures, enhancing the user experience and ensuring a firm hold when carrying the containers. Moreover, the aesthetic appeal of aluminum alloy handles and grips can be further enhanced through surface treatments like anodizing or polishing, making the packaging products more attractive on the shelves and adding value to the overall product presentation.

5. Aluminum Alloy CNC Turning: Facilitating Maintenance and Upgrades of Packaging Equipment

The use of aluminum alloy CNC – turned parts in the packaging industry also greatly facilitates maintenance and upgrades of packaging equipment, which are essential for keeping the production lines running smoothly and adapting to changing production requirements.

When a component of packaging equipment needs to be replaced or repaired, the standardized and precisely – machined nature of aluminum alloy CNC – turned parts allows for easy identification and installation. The modular design enabled by CNC turning simplifies access to internal components, reducing downtime and maintenance costs. As new packaging technologies and production demands emerge, we can use aluminum alloy CNC turning to produce upgraded parts. For example, when upgrading the automation level of a packaging machine, we can manufacture new aluminum alloy CNC – turned components with improved precision and functionality. When enhancing the energy efficiency of the equipment, aluminum alloy parts with optimized designs can be produced. The flexibility and precision of aluminum alloy CNC turning ensure that our packaging equipment can stay competitive and meet the evolving needs of the industry.