Material Selection for Automotive Aluminum Alloy CNC Turning

Choosing the right aluminum alloys is foundational to successful automotive lightweighting through CNC turned components. We primarily utilize 6061 and 7075 aluminum alloys for Aluminum Alloy CNC Turning in automotive applications, balancing strength, weight reduction, and machinability. 6061-T6 offers excellent formability and corrosion resistance, making it ideal for non-structural components like fuel system fittings and sensor housings, where weight savings of 40–50% compared to steel are achievable. 7075-T6 provides higher tensile strength (570 MPa vs. 310 MPa for 6061), suitable for structural components such as suspension pivot pins and transmission shafts requiring both lightweighting and durability. Our material selection process evaluates each part’s load requirements, environmental exposure, and manufacturing needs, ensuring the chosen alloy supports efficient Aluminum Alloy CNC Turning while meeting automotive performance standards. This strategic material choice forms the basis for lightweight components that reduce vehicle weight without compromising safety or functionality.

Structural Optimization in Aluminum Alloy CNC Turning

Designing structurally optimized components maximizes weight reduction in automotive aluminum CNC turned parts. We collaborate with engineers to implement topology optimization, identifying material redundancy in traditional steel designs and removing excess material through Aluminum Alloy CNC Turning. This approach creates hollow shafts, thin-walled housings, and lattice-like structures that maintain strength while reducing weight by 30–60%. For example, our CNC turned aluminum suspension bushings feature optimized wall thicknesses (1.5–3mm) machined to precise tolerances, eliminating unnecessary material without sacrificing load-bearing capacity. We use finite element analysis (FEA) to validate designs before manufacturing, ensuring critical stress points are reinforced in the CNC turning process. Our Aluminum Alloy CNC Turning capabilities produce complex geometries like internal oil passages and integral flanges in a single setup, avoiding the weight penalty of multi-piece steel assemblies. This structural optimization ensures each aluminum CNC turned component contributes maximally to overall vehicle lightweighting.

Precision Tolerance Control in Automotive Aluminum Alloy CNC Turning

Maintaining tight tolerances is critical for aluminum CNC turned automotive components, where precision ensures proper fit and performance in lightweight assemblies. We control dimensional tolerances to ±0.005mm for critical mating surfaces in Aluminum Alloy CNC Turning, ensuring components like aluminum fuel injectors and brake caliper pistons function reliably under operating pressures. Concentricity is maintained within 0.003mm for rotating components such as drive shafts, preventing vibration that could compromise vehicle safety. Our CNC turning centers use in-process probing to verify dimensions during production, making automatic adjustments to compensate for material variations in 6061 and 7075 alloys. For threaded components like aluminum fasteners, we control thread pitch diameter to class 6g standards, ensuring secure connections without the weight of steel hardware. This precision tolerance control in Aluminum Alloy CNC Turning ensures lightweight aluminum components perform as reliably as their heavier steel counterparts in automotive applications.

Performance Enhancement Through Aluminum Alloy CNC Turning

Aluminum CNC turned components enhance automotive performance beyond simple weight reduction through improved functional characteristics. The excellent thermal conductivity of aluminum (205 W/m·K for 6061) makes our CNC turned heat sinks and oil coolers 30% more efficient than steel alternatives, improving engine thermal management. Reduced unsprung weight from aluminum suspension components machined via Aluminum Alloy CNC Turning improves handling and ride quality by allowing better suspension response to road conditions. Our CNC turned aluminum intake manifold components feature smooth internal surfaces (Ra < 1.6μm) that reduce air flow resistance by 15–20%, increasing engine efficiency. The corrosion resistance of aluminum eliminates the need for heavy protective coatings, maintaining lightweight benefits while extending component life. We also machine aluminum components with integrated features like sensor mounting bosses, reducing assembly weight by eliminating separate steel brackets. These performance enhancements demonstrate how Aluminum Alloy CNC Turning contributes to overall vehicle efficiency beyond just weight reduction.

Cost-Effective Production in Aluminum Alloy CNC Turning

Implementing efficient manufacturing processes ensures aluminum CNC turned components deliver cost-effective automotive lightweighting solutions. Our high-speed Aluminum Alloy CNC Turning centers achieve material removal rates up to 50 cm³/min for 6061 aluminum, reducing cycle times compared to steel machining. The excellent machinability of aluminum alloys allows longer tool life—carbide inserts last 3–5× longer in Aluminum Alloy CNC Turning than in steel turning operations, reducing tooling costs. We optimize nesting of multiple components from single aluminum billets, achieving material utilization rates above 85% and minimizing waste. Our automated production cells for high-volume components like aluminum wheel studs combine CNC turning with robotic handling, reducing labor costs while maintaining consistency. While aluminum raw material costs more than steel, the total cost difference is offset by reduced machining time, lower tooling expenses, and elimination of secondary coating processes in Aluminum Alloy CNC Turning. This cost-effectiveness makes aluminum CNC turned components a viable lightweighting solution for mass-produced vehicles.

Application-Specific Aluminum Alloy CNC Turning Solutions

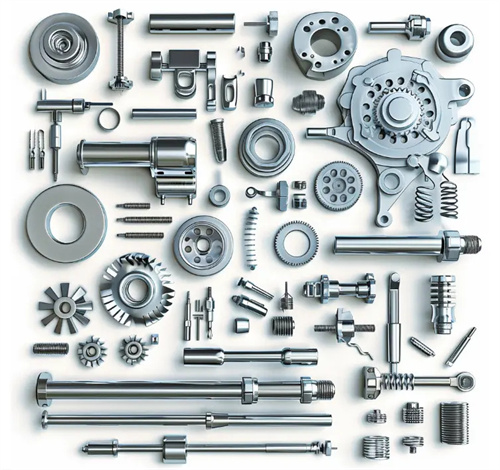

Targeted applications of aluminum CNC turned components deliver maximum lightweighting benefits across vehicle systems. In powertrains, our CNC turned aluminum crankshaft pulleys and timing gears reduce rotational inertia by 40–50%, improving fuel efficiency. Chassis components including aluminum control arm bushings and steering knuckles, produced through precise Aluminum Alloy CNC Turning, reduce unsprung weight to enhance handling. Body-in-white applications feature aluminum CNC turned fasteners and brackets that cut weight without compromising structural integrity. Our aluminum heat exchanger end caps, machined with complex port geometries via Aluminum Alloy CNC Turning, improve cooling efficiency in electric vehicle battery systems. Interior components like aluminum seat adjuster mechanisms offer weight savings while providing a premium feel. Each application leverages the specific advantages of aluminum—weight reduction, thermal conductivity, or corrosion resistance—through optimized Aluminum Alloy CNC Turning processes, contributing to lighter, more efficient vehicles across all automotive segments.