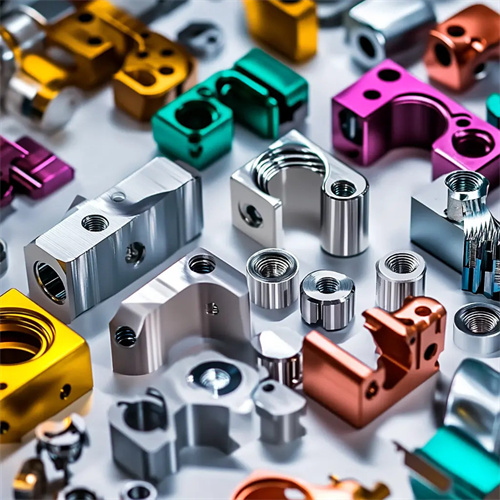

In the dynamic and creative realm of the toy industry, aluminum alloy CNC turning has become an indispensable and transformative technology for us. As we aim to craft toys that captivate young minds, prioritize safety, and endure the test of enthusiastic play, this advanced manufacturing approach unlocks a world of possibilities. The exceptional attributes of aluminum alloys, such as their lightweight composition, remarkable strength, and resistance to wear and corrosion, when coupled with the pinpoint accuracy and adaptability of CNC turning, empower us to produce a wide array of components that elevate toy design to new heights. From enhancing functionality to adding aesthetic allure, aluminum alloy CNC turning is reshaping the landscape of the toy industry.

1. Precision – engineered Functional Parts by Aluminum Alloy CNC Turning in Toys

For toys that rely on mechanical movement and interactive functions, precision – engineered parts are the key to a seamless play experience, and aluminum alloy CNC turning excels in this regard. In mechanical building block toys, we utilize aluminum alloy CNC – turned axles and pins with meticulous precision. The exacting machining process guarantees that each axle has a consistent diameter and smooth surface, enabling blocks to rotate and connect effortlessly. This precision allows children to construct complex structures with ease, fostering their creativity and problem – solving skills. In electronic learning toys, aluminum alloy CNC – turned connectors are crucial for establishing stable electrical connections. These connectors are manufactured with tight tolerances, ensuring reliable signal transmission between components, which is essential for the proper functioning of features like interactive quizzes and sound effects. The precision – crafted functional parts made through aluminum alloy CNC turning not only enhance the usability of toys but also contribute to their long – term reliability.

2. Lightweight yet Sturdy Toy Frames with Aluminum Alloy CNC Turning

Striking a balance between a toy’s weight and durability is essential, and aluminum alloy CNC turning offers an optimal solution for creating toy frames. In large – scale playsets like playhouses, we employ aluminum alloy CNC – turned frames to provide a sturdy foundation. The lightweight nature of aluminum alloys makes the playhouse easy to assemble and move, while its high strength ensures that it can withstand the rough and tumble of active play. For instance, the frame of a wooden – themed playhouse, reinforced with aluminum alloy CNC – turned corner brackets, can endure children climbing in and out, as well as the weight of attached accessories like swings or slides. Similarly, in handheld gaming devices designed for kids, aluminum alloy CNC – turned casings offer a lightweight and durable enclosure. These casings protect the internal electronics from accidental drops and bumps, while their reduced weight makes the devices comfortable for children to hold during extended play sessions.

3. Eye – catching Decorative Accents by Aluminum Alloy CNC Turning in Toys

Aesthetics play a significant role in attracting children to toys, and aluminum alloy CNC turning allows us to create visually stunning decorative accents. In collectible figurines, we use aluminum alloy CNC – turned armor pieces and accessories to add a touch of realism and elegance. These components can be intricately designed with detailed engravings, patterns, or textures, such as the scales on a dragon figurine’s armor or the emblems on a knight’s shield. The smooth and polished surface finish achieved through CNC turning gives these decorative accents a high – quality appearance, making the figurines more appealing to collectors and children alike. In ride – on toys, aluminum alloy CNC – turned trim pieces and badges enhance the overall visual appeal. Whether it’s a shiny emblem on the front of a toy car or a decorative strip along the side of a tricycle, these accents not only make the toys look more attractive but also contribute to brand recognition.

4. Safe and Reliable Toy Components Assured by Aluminum Alloy CNC Turning

Safety is the cornerstone of toy manufacturing, and aluminum alloy CNC turning helps us ensure that our products meet the strictest safety standards. Aluminum alloys are inherently non – toxic, making them an ideal material for children’s toys. Through the precise control of CNC turning, we can eliminate sharp edges and corners on toy components, minimizing the risk of injury. For example, in toy tool sets, aluminum alloy CNC – turned handles are designed with rounded edges and ergonomic shapes, providing a comfortable and safe grip for small hands. Additionally, the durability of aluminum alloy components reduces the likelihood of parts breaking or detaching during play, preventing potential choking hazards. The precision machining also allows for accurate sizing of components, ensuring that they are too large to be swallowed by children. By using aluminum alloy CNC turning, we can produce toys that parents can trust and children can enjoy safely.

5. Customizable and Innovative Toy Designs Enabled by Aluminum Alloy CNC Turning

In a highly competitive toy market, customization and innovation are essential for standing out, and aluminum alloy CNC turning offers us the flexibility to create unique toy designs. We can easily customize components according to specific themes, branding requirements, or individual preferences. For limited – edition toys or promotional items, we use aluminum alloy CNC turning to create custom – engraved names, logos, or special messages on toy parts. This personalization adds value and makes the toys more collectible. Moreover, the technology allows us to experiment with unconventional shapes and structures, enabling the development of innovative toys that push the boundaries of traditional design. For example, we can create toys with organic, flowing forms or incorporate complex geometric patterns that were previously challenging to achieve. This ability to customize and innovate with aluminum alloy CNC turning not only meets the diverse demands of consumers but also drives the continuous evolution of the toy industry.